Anycubic Kossel Plus

BL / 3D Touch Setup

Hardware

- Print bracket such as: http://www.thingiverse.com/thing:2251115

- Connect White/Black wire to z-min-endstop (S = (signal - white), - = (minus - black)). Orientation doesn't matter

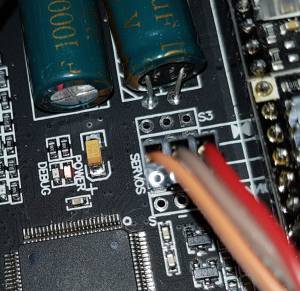

- Connect Brown/Red/Orange wire to servo 0 port (S = Orange, + = Red, - = Brown) NOTE: on the Tri Gorila Board + and - are reversed.

- Powering on system should make LED light red and move the pin a few times

Software (Marlin)

Using release from Anycubic: https://drive.google.com/drive/u/0/folders/0B8VIB533cgdMa1czMW5hNWlXYW8 Some of these may already be set.

#define MOTHERBOARD 43 // using 33 doesn't work #define BLTOUCH // turn on probe // these values strongly depend on your mount! #define X_PROBE_OFFSET_FROM_EXTRUDER 36.1 // X offset: -left +right [of the nozzle] #define Y_PROBE_OFFSET_FROM_EXTRUDER -29 // Y offset: -front +behind [the nozzle] #define Z_PROBE_OFFSET_FROM_EXTRUDER -3.6 // Z offset: -below +above [the nozzle] #define XY_PROBE_SPEED 6000 #define Z_MIN_PROBE_USES_Z_MIN_ENDSTOP_PIN #define Z_CLEARANCE_DEPLOY_PROBE 50 // Z Clearance for Deploy/Stow #define Z_CLEARANCE_BETWEEN_PROBES 10 // Z Clearance between probe points #define AUTO_BED_LEVELING_BILINEAR // works better but still not ideal #define SAFETY_MARGIN 5 #define DELTA_PROBEABLE_RADIUS (DELTA_PRINTABLE_RADIUS - sqrt(sq(X_PROBE_OFFSET_FROM_EXTRUDER)+sq(Y_PROBE_OFFSET_FROM_EXTRUDER)) - SAFETY_MARGIN ) // #define DELTA_PROBEABLE_RADIUS (DELTA_PRINTABLE_RADIUS -10) #define LEFT_PROBE_BED_POSITION -(DELTA_PROBEABLE_RADIUS) #define RIGHT_PROBE_BED_POSITION DELTA_PROBEABLE_RADIUS #define FRONT_PROBE_BED_POSITION -(DELTA_PROBEABLE_RADIUS) #define BACK_PROBE_BED_POSITION DELTA_PROBEABLE_RADIUS

Test the probe works

Send G codes M280 P0 S10 and M280 P0 S90. Probe should extend on first command and retract on second.

Finding probe to hotend offset (Marlin)

- make a mark on the bed with a pen or sticker

- Move the hotend to this exact location (use G codes, e.g.

G1X10Y-10Z10moves the probe to X +10mm, Y -10mm and Z +10mm) - Put a paper under the probe and move it until the paper sticks a bit. Use

G1Z5,G1Z4etc. until you reach the paper - Reset all values to Zero:

G92 X0 Y0 Z0 - Move the hotend off the mark

G1Z10 - Now move the probe exactly over the mark using G codes like above

- once you are exactly on the mark extend the probe with

M280 P0 S10(if the probe doesnt move reset it withM280 P0 S260) - start lowering the probe slowly using

G1Z9,G1Z8etc. once you are close start adding decimals - when the probe activates note down the numbers on the LCD.

- In my case I had

X-36.1 Y 29 Z 3.6, now enter the offsets in Configuration.h (NOTE: X shows a negative, that means enter it possitve in Marlin, Y is entered as a negative. )

Trigger Auto Leveling

- Enable logging to see what is going on

M111 S247 - Zero Z, using

G28 - Level Bed

G29(useG29 V4to see more log info)

Update Slicer

- In your slicer make sure you set the printer to do a

G28then aG29before each print.

NOTICE: Doing a G28 resets the autolevel values! I am still trying to figure out how to get Octoprint to not reset my auto level values before printing.